For Healthcare Professionals

Documents

Case Flow Process

STARTING A CASE

1. Patient Data

CT, CBCT, Intraoral Scan, Etc.

Each Custom Surgical Solution starts with patient scan data. The more accurate the data, the more accurate the service or product MedCAD can deliver. It is important to distribute our CT Scan Protocol to your respective radiology department to ensure proper scan resolution.

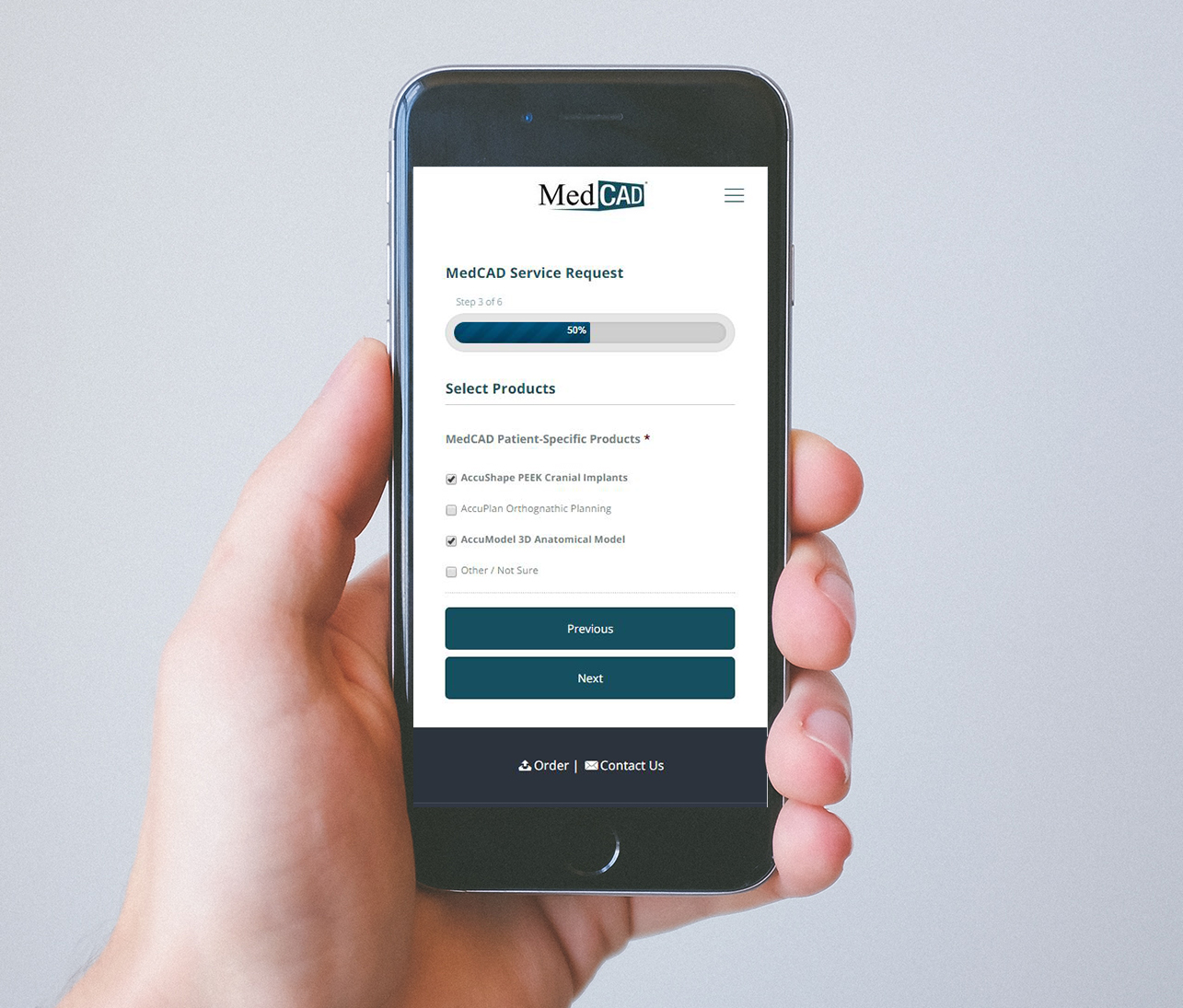

2. Service Request

Online or Paper

Once you have patient scan data, you can start a case using our quick Online Service Request. This will include logistics, ordering, scheduling a planning session (if applicable) and upload / shipping steps, all in one.

The Service Request can be filled out via mobile phone, tablet and computer. PDF versions of the Service Requests are available on each product page.

CUSTOMIZATION PROCESS

3. Planning Session

Depending on Product

Once all case requirements are sent to MedCAD, our design team will prepare the preoperative scan data for a Surgical Planning Session with the surgeon. In the planning session, we go through each measurement and movement to simulate the surgery and design the patient-specific medical devices.

You can schedule your Surgical Planning Session within the Online Service Request if a session is required. Easily find available times or reschedule without having to go back-and-forth with Customer Support. Planning Sessions can also be scheduled by contacting Customer Support.

A Surgical Planning Session may take between 10 and 45 minutes depending on surgeon preference, case complexity and quality of patient data.

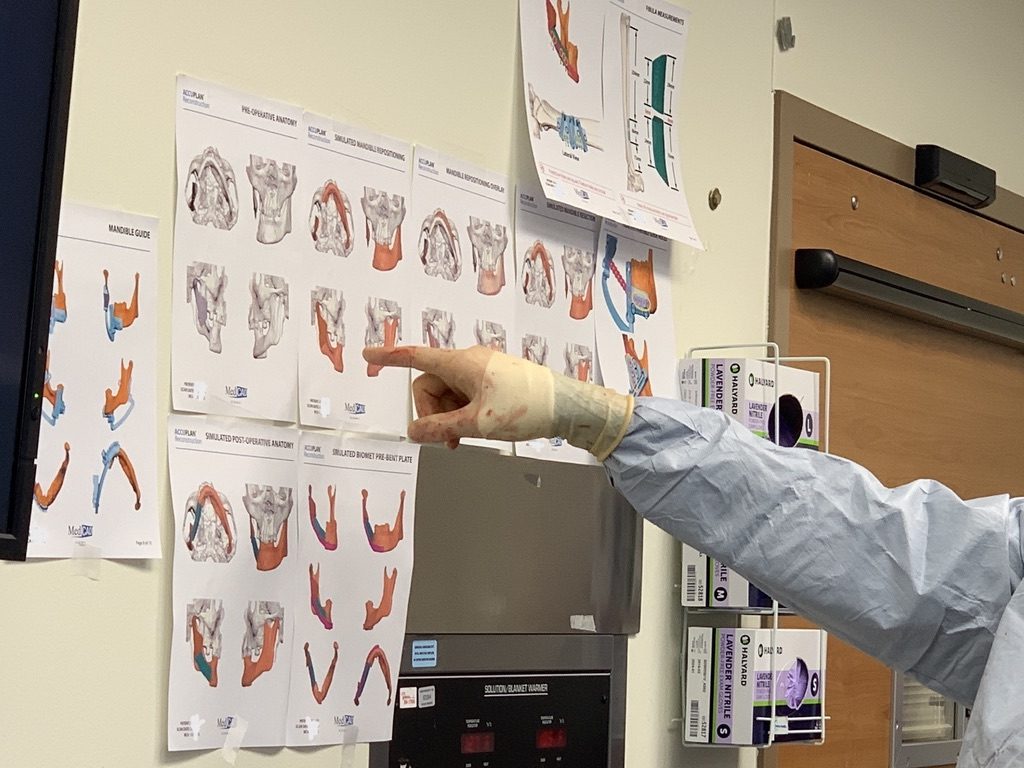

4. Surgical Plan

Shortly after the Surgical Planning Session, our team will finalize the design as directed by the surgeon and deliver a surgical plan for review. This plan includes metrics, visuals, measurements, deliverables and case details for reference in surgery.

The surgeon must provide written approval of the surgical plan to proceed to manufacturing of medical devices.

PRODUCT FULFILLMENT

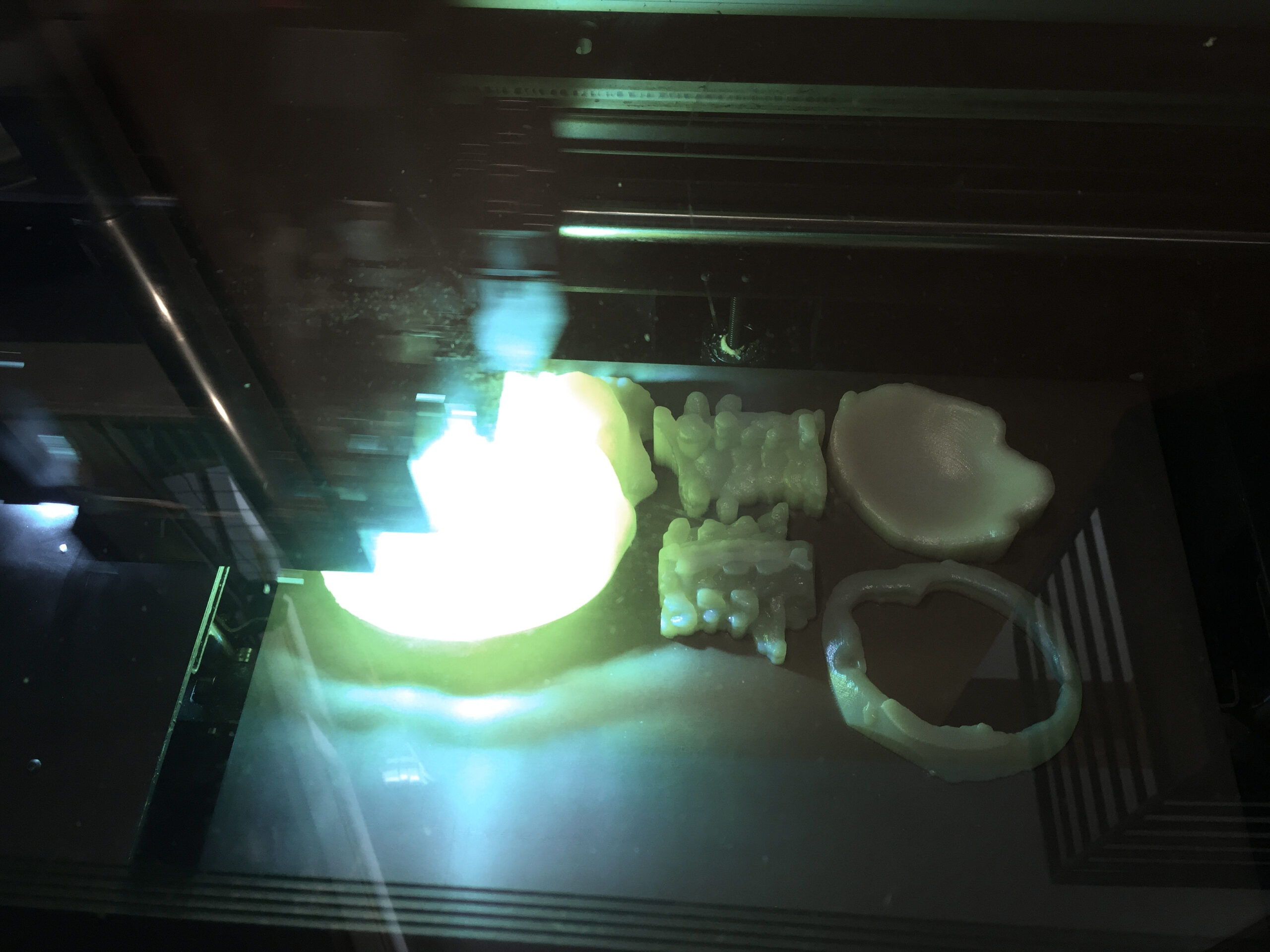

5. Manufacturing

Once the surgical plan is approved, the patient-specific medical devices within that plan are sent to manufacturing. MedCAD employs a variety of manufacturing techniques, such as 3D printing and multiaxis milling to produce our Custom Surgical Solutions.

6. Clinical Application

Manufactured parts are expedited to the customer in time for the cleaning and sterilization procedures found in the Instructions for Use document.