AccuShape®

Neuro

Overview

Sculpted Precision, Surgical Artistry

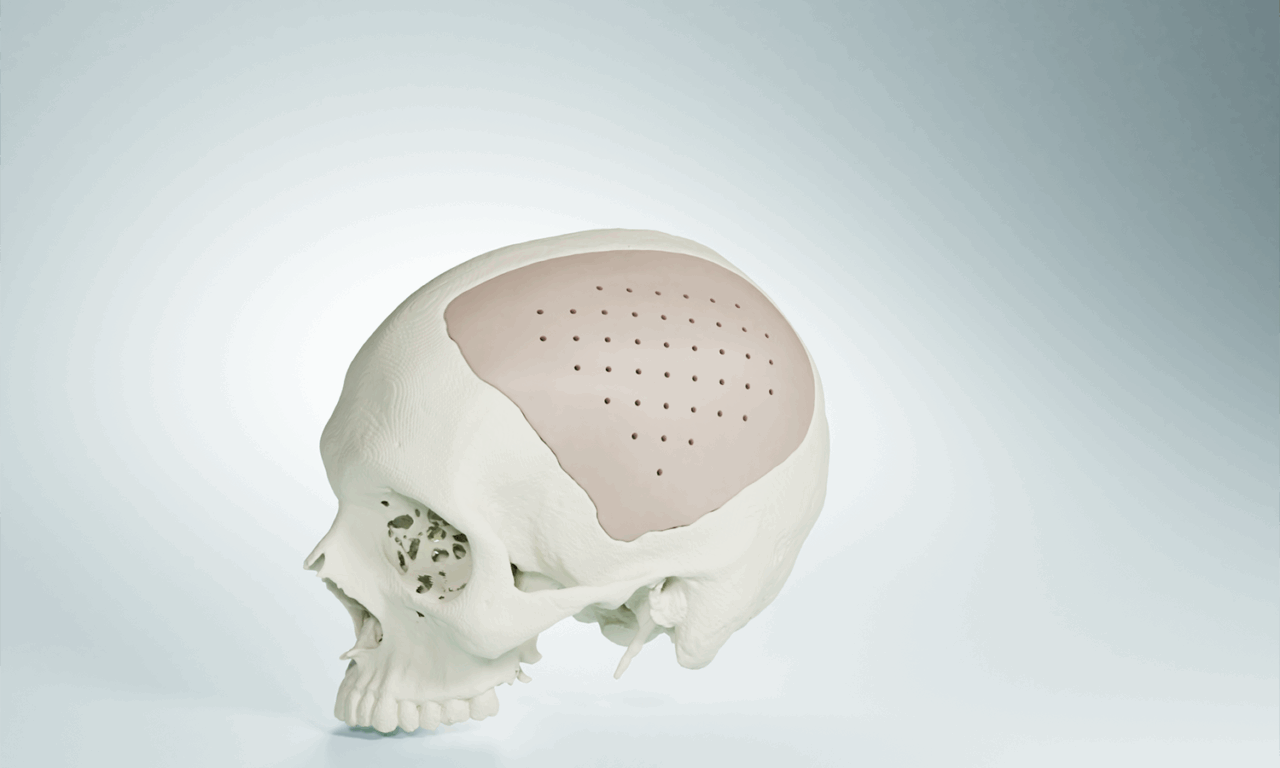

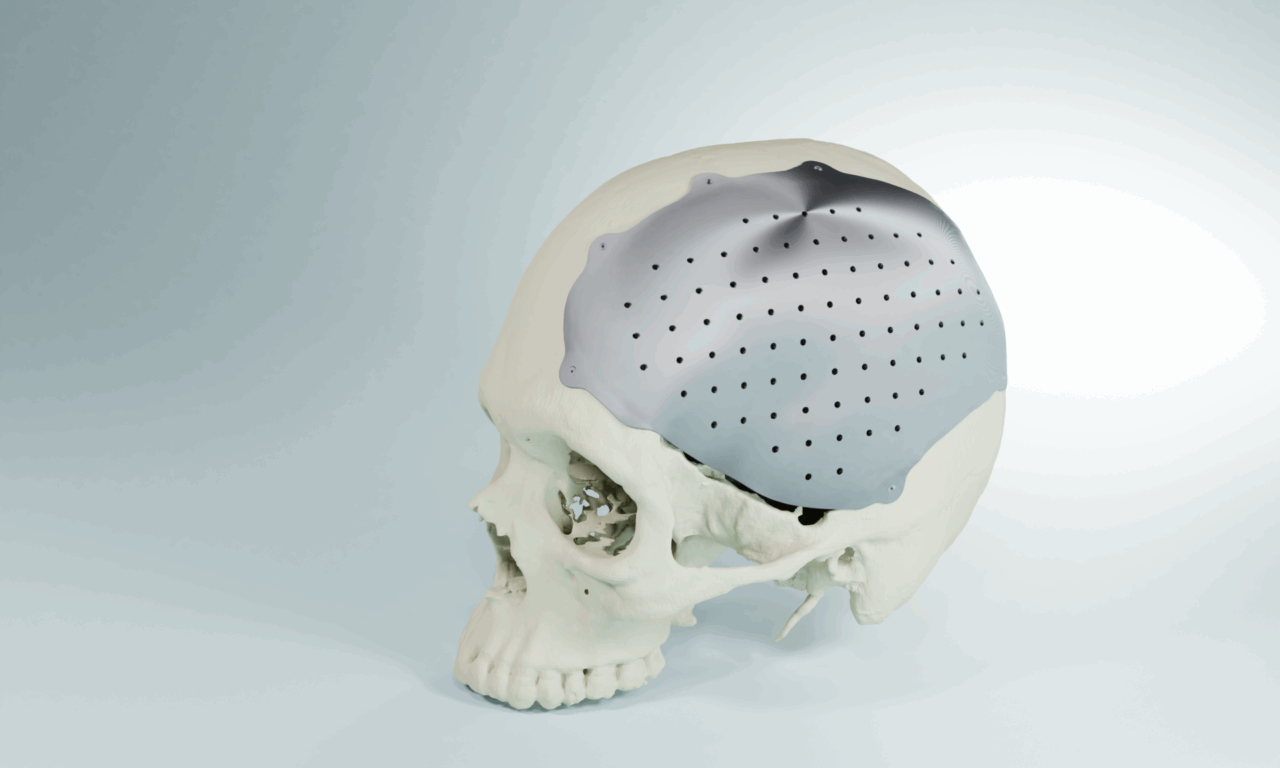

AccuShape Cranial Implants in PEEK or 3D Printed Titanium are designed from detailed patient CT data for conditions including cranioplasty, temporal hollowing, and bone flap replacement. AccuShape PEEK closely matches the strength and characteristics of cortical bone for a biocompatible, radiolucent, and fast-delivery design. AccuShape Titanium uses a medical-grade titanium alloy for a robust, biocompatible solution. Either enables complex anatomical solutions with resolution contouring and no need for fixation plates, and are fully compatible with all approved neuro fixation screws.